Ever wondered how the pristine purity of the liquids we use in labs and industries is achieved? The answer lies in the unsung hero of many processes: the solvent filter.

Solvent filtration, though often overlooked, is an essential process that impacts everything from the efficacy of life-saving pharmaceuticals to the reliability of advanced chemical processes. If you've ever marveled at the clarity of a scientific solution or trusted a product made with impeccable precision, a solvent filter likely played a crucial role.

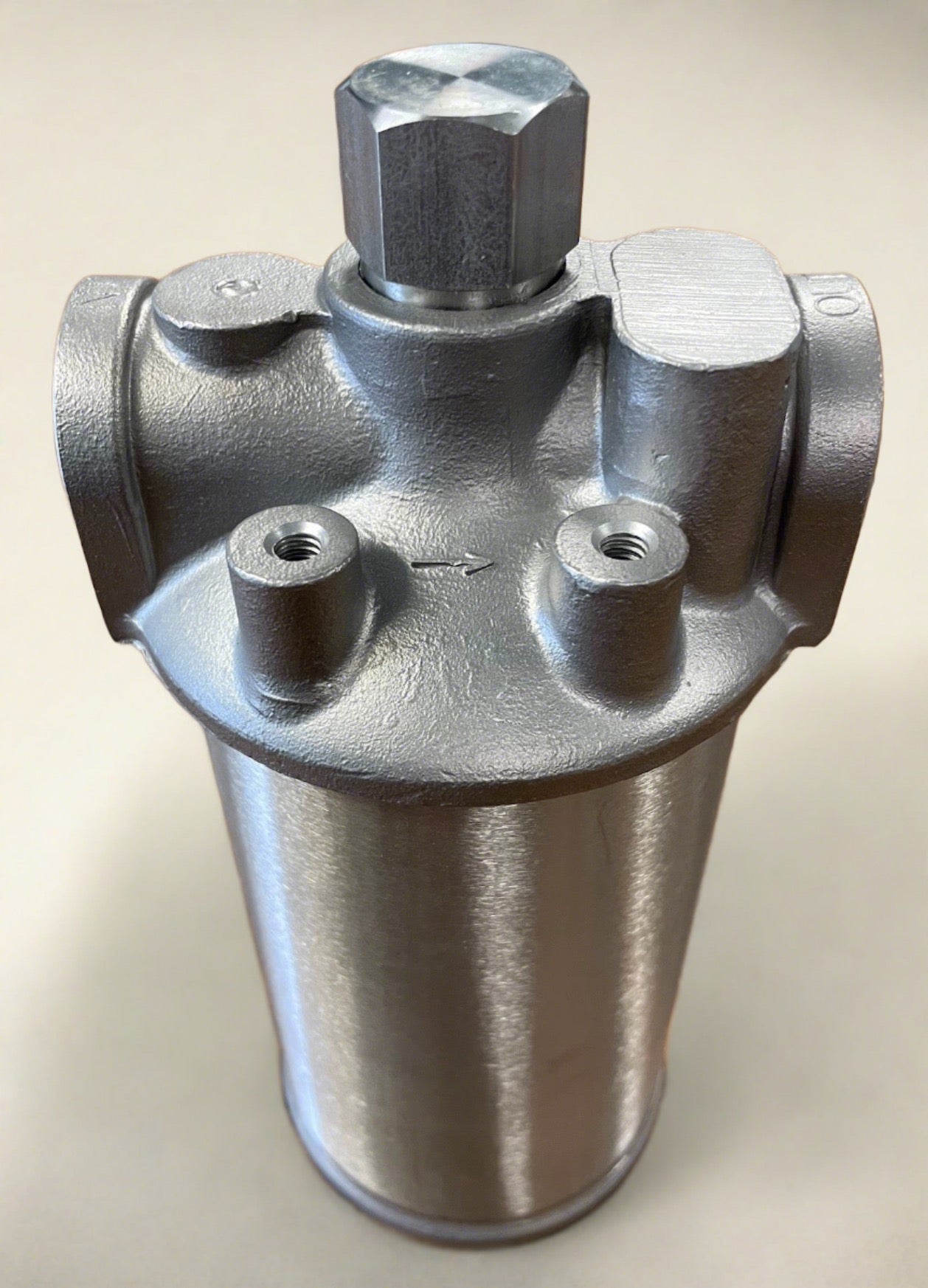

A solvent filter is, at its core, a sophisticated device or system designed to remove impurities from solvents. Think of it as a guardian that ensures solvents are free from unwanted particles, debris, and other contaminants. It's not merely about cleanliness; it's about upholding the integrity of scientific processes and the quality of the final product. These filters come in an array of shapes and sizes, each carefully tailored for its intended purpose. Whether you're working in a cutting-edge laboratory or overseeing a large-scale industrial operation, selecting the right solvent filter can make all the difference.

- Discover Kannada Movierulz History The Future Of Sandalwood

- Movierulz Hd Kannada Risks Alternatives Safe Streaming Guide

| Feature | Details |

|---|---|

| Definition | A device or system used to remove impurities from solvents. |

| Purpose | To ensure solvents are free from particles, debris, and contaminants, maintaining the integrity of processes and products. |

| Applications | Pharmaceuticals, Chemical Processing, Environmental Testing, and various industrial and laboratory settings. |

| Types | Syringe Filters, Membrane Filters, Cartridge Filters |

| Materials (Membrane Filters) | PTFE, Nylon, Polypropylene, and others. |

For more information, visit: Example Website

Why are solvent filters so critical? Because impurities in solvents can wreak havoc on experiments, compromise product quality, and even create safety risks. Solvent filters act as a barrier, ensnaring unwanted particles and allowing only the pure solvent to pass through. Consider, for instance, the pharmaceutical industry, where even the smallest contaminant can undermine a drug's effectiveness or, worse, its safety. In chemical processing, impurities can clog equipment or trigger unexpected reactions, leading to defects. The use of solvent filters ensures that solvents are as pristine as possible, safeguarding quality and upholding safety standards.

Key Benefits of Using Solvent Filters

- Improved product quality

- Enhanced process efficiency

- Reduced risk of contamination

- Longer equipment lifespan

- Compliance with industry regulations

Not all solvent filters are created equal, and choosing the right one hinges on understanding the various types available. Here's a breakdown of the most common:

- Lara Rose Telegram Secrets Of A Digital Influencers Success

- Decoding The Pining For Kim Video Origins Impact Why It Matters

Syringe Filters

Syringe filters are the workhorses of small-scale applications. These compact, user-friendly devices are frequently used in laboratories to filter small volumes of solvents before analysis or experimentation. They are the versatile Swiss Army knives of the filtration world convenient and adaptable.

Membrane Filters

Membrane filters are the heavy-duty champions of the solvent filtration arena, designed for large-scale operations and high volumes of solvents. These filters are constructed from diverse materials, including PTFE, nylon, and polypropylene, each with its unique advantages and suitability for specific applications.

Cartridge Filters

Cartridge filters are ideally suited for industrial applications where the need to filter large quantities of solvents is paramount. They are known for their durability, efficiency, and adaptability to meet specific requirements. If you're running a factory or plant, cartridge filters are a must-have.

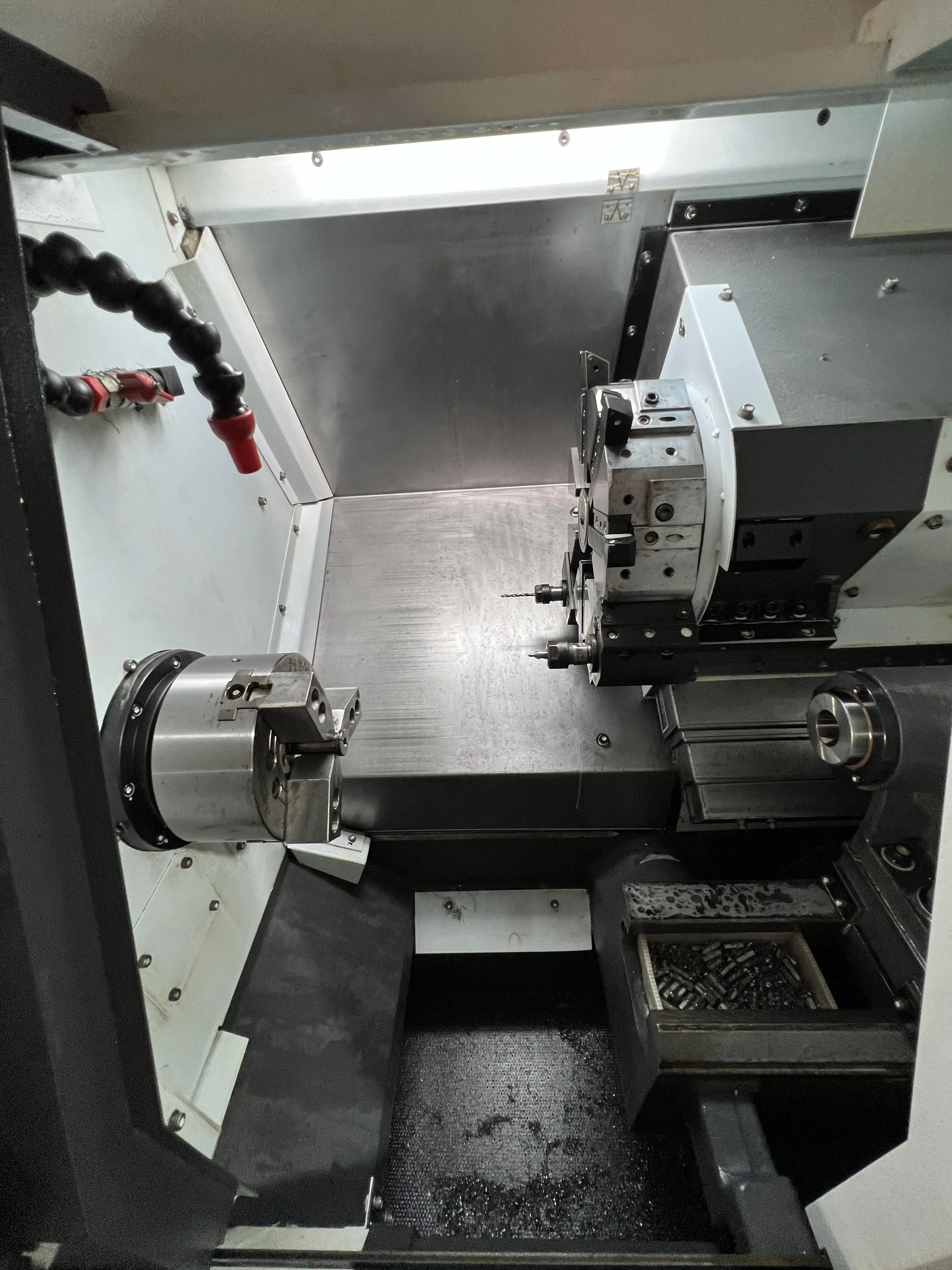

The science behind solvent filtration is truly fascinating. In essence, these filters work by allowing the solvent to pass through while simultaneously capturing particles and impurities. This is achieved through a combination of physical barriers and chemical interactions.

For example, membrane filters feature microscopic pores that permit only solvent molecules to pass through, effectively blocking larger particles. Some filters employ adsorption, where contaminants adhere to the filter material, guaranteeing that only the purest solvent emerges on the other side.

Choosing the right solvent filter can be a daunting task, given the wide array of options. However, the process can be streamlined with a few key considerations:

- Consider the type of solvent youre working with

- Determine the size of particles you need to remove

- Think about the volume of solvent youll be filtering

- Evaluate the compatibility of the filter material with your solvent

- Check the filters flow rate and pressure requirements

By addressing these questions, you can narrow down the choices and pinpoint the solvent filter that best aligns with your specific needs.

Solvent filters are utilized across a broad spectrum of industries, each with unique applications. Lets delve into some of the most prevalent:

Pharmaceutical Industry

In the pharmaceutical industry, solvent filters are indispensable. They ensure drug formulations are free from contaminants, which is critical for patient safety. Whether its during the manufacturing process or quality control testing, solvent filters play a pivotal role in maintaining product purity.

Chemical Processing

Chemical processing plants rely heavily on solvent filters to maintain the smooth operation of their facilities. By removing impurities from solvents, these filters prevent equipment damage, reduce downtime, and increase overall efficiency.

Environmental Testing

Accuracy is of the utmost importance in environmental testing. Solvent filters are crucial in ensuring that samples are free from contaminants, which allows for more reliable and precise results. This is especially true when monitoring water quality or air pollution levels.

While solvent filters are undeniably valuable, they also present their own set of challenges. Common issues include clogging, low flow rates, and compatibility problems. Lets examine these more closely:

- Clogging: This occurs when the filter becomes blocked with particles, reducing its effectiveness.

- Low Flow Rates: Some filters may not allow solvents to pass through quickly enough, slowing down your processes.

- Compatibility Issues: Not all filter materials are compatible with every solvent, which can lead to chemical reactions or filter degradation.

To mitigate these challenges, it's essential to select the right filter for the application and maintain it properly.

Just like any other piece of equipment, solvent filters require regular maintenance to function correctly. Here are a few best practices to keep in mind:

- Follow the manufacturers guidelines for cleaning and replacement

- Inspect filters regularly for signs of wear or damage

- Store filters in a clean, dry place to prevent contamination

- Train staff on proper filter handling and maintenance procedures

By taking proper care of solvent filters, you ensure they continue to perform at their peak for years to come.

The field of solvent filtration is constantly evolving, with new technologies and innovations emerging all the time. Current trends include:

- Smart filters that provide real-time data on performance and condition

- Environmentally friendly materials that reduce waste and carbon footprint

- Advanced membrane technologies that improve efficiency and capacity

As these trends develop, we can expect solvent filtration to become even more precise, efficient, and sustainable.

In conclusion, solvent filters are indispensable tools in the modern world. These filters are crucial to maintaining product quality and are essential in various applications and industries. Whether you're a scientist, engineer, or simply someone with a curiosity about the science of purification, understanding the role of solvent filters can open up a world of possibilities.

If you found this article helpful, share it with your friends and colleagues. Stay curious and keep learning.

Here is a Table of Contents for quick navigation:

- What Exactly is a Solvent Filter?

- Why Are Solvent Filters Important?

- Key Benefits of Using Solvent Filters

- Types of Solvent Filters

- How Do Solvent Filters Work?

- Choosing the Right Solvent Filter

- Applications of Solvent Filters

- Common Challenges in Solvent Filtration

- Best Practices for Maintaining Solvent Filters

- Future Trends in Solvent Filtration

- Whitney Wisconsins Death What You Need To Know

- Kannada Movies In 2024 Stream Legally Avoid 5movierulz